Harley Davidson Exhaust Bolt Torque

Discussion Starter 1 Mar 6 2008.

Harley davidson exhaust bolt torque. You may have to remove the heat shields in order to access the bolts on all the flanges and use antiseize compound all that heat and corrosion will make things tough the next time. Locate the flangeor flat rimon both the torque cones and the exhaust. The torque values I found for that size thread gives 8 ftlbs for a steel to steel interface.

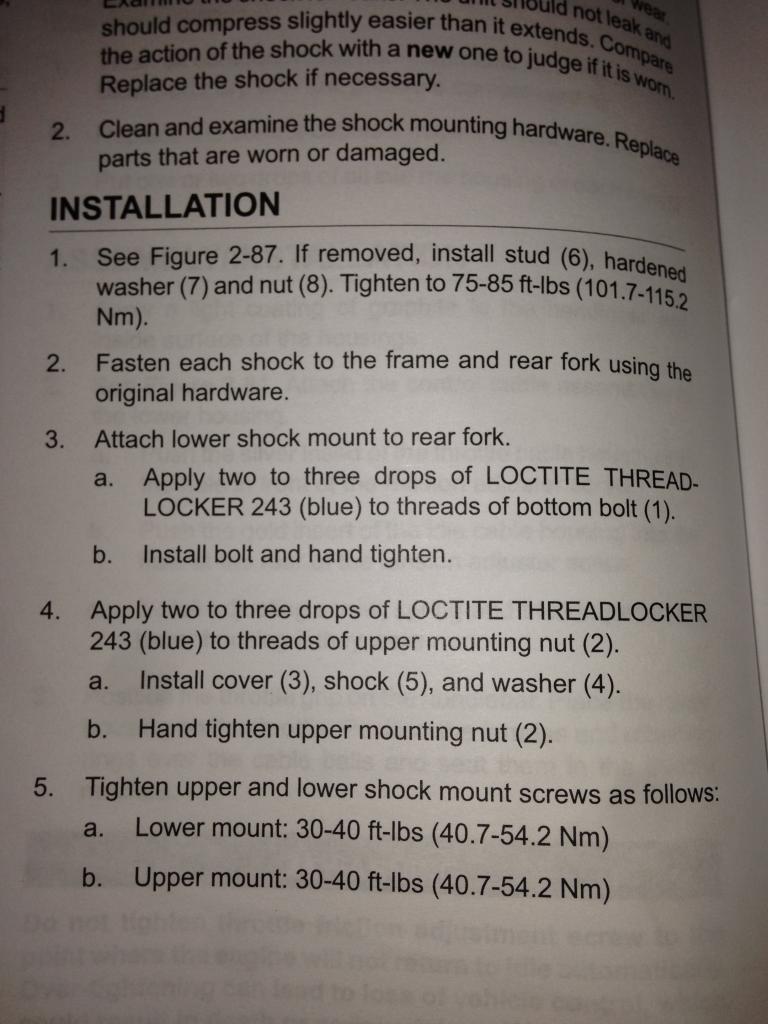

Exhaust Torque specs. If applicable remove OEM O2 sensors from the OEM pipes and install in both front and rear. 3 Tighten each bolt to 22-25 foot pounds of torque.

516 - 19 ft. Exhaust bolt torque spec. Be careful not to over-tighten.

I would tighten the TORCA clamps to 45-60 ft-lbs. Hi all How much torque is required for the nuts on head pipe flange. You get a feel for the torque by taking a torque wrench and turning to the specified torque on something else to get the feel for the specified torque.

I hope I explained this where you can understand this. Then you torque the specific part. The nfieldgear catalog says the correct torque is 4 ftlbs 48 inlbs.

Jump to Latest Follow 1 - 10 of 10 Posts. Stock Pushrod Color Codes. Harley-davidson Torque Spec Chart.